30

Oct

TR Lab: research and development for innovative wheels in all industrial fields

Contents

- Introduction

- How is the activity of the research and development laboratory in industrial wheels organised?

- Innovative solutions for industrial wheels

- Testing services

- Conclusions

Introduction

It is easy to guess that a detailed and specific research and development activity lies at the basis of technological innovations, in a vast and transversal sector such as industrial wheels.

To support this, we can mention the TRLab Test&Research laboratory in Iberruedas as an example.

It is a structure purely dedicated to scientific research in the industrial field. The activity of the laboratory is devoted to wheels and castors, through the research, development and testing of innovative solutions in order to meet the handling needs of customers working in the industrial field.

Since 2011 TR Lab has been awarded with the High-Tech Network accreditation of the Emilia-Romagna region,

How the activity of the research and development laboratory in industrial wheels is organised

More specifically, the activity of the laboratory consists in:

- Proposing innovative solutions for materials and technologies;

- Defining the ideal size characteristics of wheels and castors according to the required functionality and price;

- Testing services on elastomeric, thermoplastic and metallic materials and on the finished wheel (according to international standards and specific customer requirements)

Let us make these activities as clear as possible.

Innovative solutions for industrial wheels

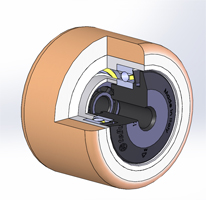

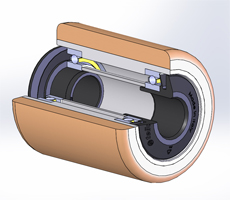

The TRLab - Test & Research laboratory at Iberruedas has among its tasks to identify, develop and characterise polyurethane compounds capable to respond to the specific application needs requested from the users of industrial wheels.

The TRLab - Test & Research laboratory at Iberruedas has among its tasks to identify, develop and characterise polyurethane compounds capable to respond to the specific application needs requested from the users of industrial wheels.

The compounds of all polyurethanes for innovative wheels were created in the research and development laboratory: from polyurethane “TR”, excellent in rolling resistance and resistance, to the soft polyurethane "TR Roll", which combines the resistance of the polyurethane and the elasticity of rubber, to the special polyurethanes, with high grip, specific electrical resistance, antistatic and/or conductive characteristics, with specific electrical resistance, and much more.

The research also addresses to thermoplastic materials, with the aim of offering wheels made of materials that combine resistance to specific application requirements, respect for the environment and a fair quality/price ratio. Many innovative Iberruedas products have been created from this field of research, such as glass-reinforced polyamide wheels for high temperatures, conductive polyamide wheels, and many others.

In-depth studies are carried out on components made of metallic materials, in order to create castors with excellent performance even in case of heavy-duty use. A specific commitment is devoted to surface treatments of metals (galvanising, painting, etc.), to protect components from corrosion in different use environments.

Thanks to the use of 2D and 3D design software and finite element analysis, the researchers of the development laboratory for new innovative wheels define the ideal dimensional characteristics of wheels and castors according to the functionality and the price requested.

New product designs are then analysed using forecasting models of the dynamic, thermal, fatigue, and vibration behaviour of the wheel tread.

The prototypes, made in Iberruedas plants, are tested using the testing equipment and then run on trial with the collaboration of customers.

Testing services

In addition to the research activities, TRLab provides the industrial companies testing services on industrial wheels and castors, as well as on elastomeric, thermoplastic and metal materials, in particular:

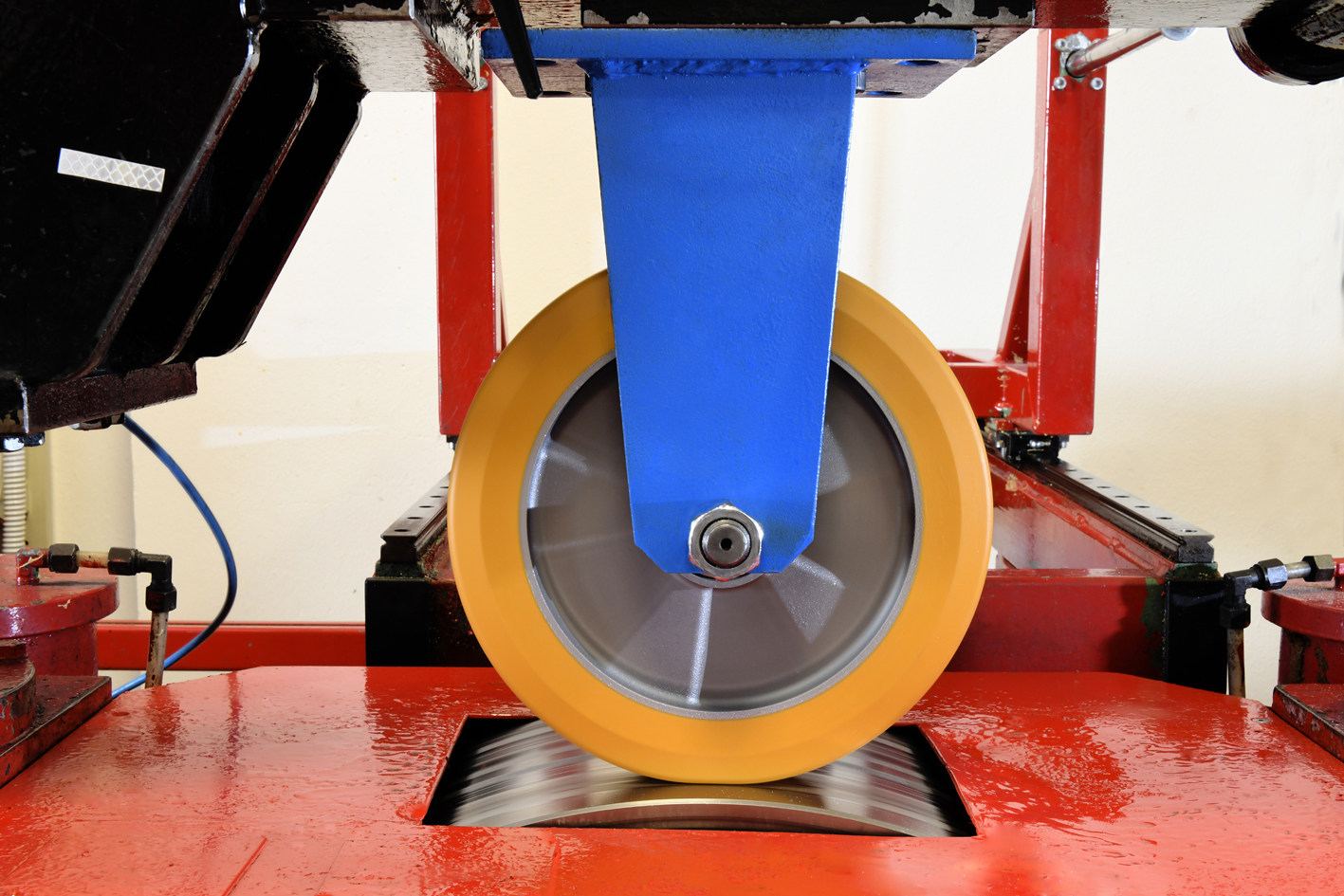

Dynamic testing on wheel and castor according to ISO 22883:2004 or ISO 22884:2004 (wheels and castors for manually propelled or power-towed industrial applications)

Dynamic testing on wheel and castor according to UNI EN 840-5:2004 (wheels and castors for waste collection containers)

Dynamic testing on wheel and castor according to ISO 22881:2004 (wheels and castors for manually propelled institutional equipment)

Compliance tests on wheel and castor with UNI EN 1004:2005; the test is carried out on static load and braking efficiency (scaffolding sector). Compliance requires the 2 tests to be carried out on a total of 5 identical units.

Rolling resistance tests according to UNI 11330 or depending on customer's choice (determination of the towing/load force curve at no. 5 - 7 increasing loads)

Braking efficiency tests according to ISO 22883:2004 o ISO 22884:2004, including braking system operating test

Physical-mechanical characterisation tests of elastomers and vulcanised rubbers (traction, tearing, abrasion, resilience, density, hysteresis)

Static load tests according to ISO 22881:2004 (wheels and castors for institutional applications)

Static load tests for complete wheels and castors for industrial use (with modalities to be agreed with the customer)

Corrosion resistance tests in neutral salt spray chamber according to UNI ISO 9227

The tests are all carried out within TR Lab, which has the instrumental equipment and the necessary know-how to carry out the tests.

At the end of the test the customer receives a Test Report with the results obtained.

Conclusions

As a guarantee to customers and new customers interested in research and development activities in the field of industrial wheels, it should be recalled that TR Lab can count on 6 researchers, coordinated by the technical-scientific director, Pierluigi Borghi.

Iberruedas S.p.A. and the laboratory obtained the Quality Certification (according to ISO 9001:2015), the Environmental Certification (according to ISO 14001:2015), and the Occupational Health and Safety Certification (according to ISO 45001:2018).

The laboratory has been working in close cooperation with external research bodies for many years and has been awarded with the High-Tech Network accreditation of the Emilia-Romagna region.

Are you interested in knowing the types of industrial wheels best suited to your specific needs, through a dedicated consultation? Contact our technicians to get a no-obligation consultation specific to your project.