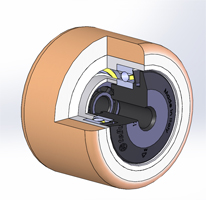

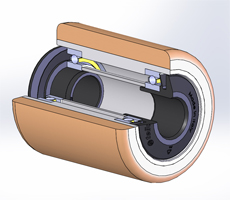

Specifically designed for::

• assembly on electric pallet trucks, both walk-behind model and with operator on board

• ensuring a longer product life under continuous mechanical handling

Technical features

Iberruedas has been designing and manufacturing wheels and castors for industrial, civil and domestic applications since 1953.

The company currently serves over 2000 customers in more than 70 countries, thanks to the professionalism of its 170 employees, who work in the company's 15,000 m2 manufacturing facilities in Formigine in the north Italian province of Modena.

The Iberruedas catalogue contains an extensive range of products designed to meet the most common handling requirements in the industrial, institutional and furniture sectors.

In addition to the catalogue range, the Iberruedas Technical Department and "TR Lab" testing & research facility work alongside customers to develop customized solutions in terms of materials, dimensions, and construction solutions to create a seamless fit with specific requirements.

Since 2000, Iberruedas has also been operating in Latin America through its subsidiary Iberruedas do Brasil

That's how Iberruedas's founder and honorary president sums up the corporate mission.

The search for cutting edge solutions is a long-standing hallmark of the company's operations, working day by day towards continual improvement of products, process and customer service.

Consistently high quality, the drive to develop innovative solutions and attention devoted to the people working in the organisation and the surrounding environment are the core values guiding Iberruedas's daily operations.

It 1950 that Iberruedas honorary president Roberto Lancellotti incorporated the small manufacturing company that was to specialise in the manufacture of wheels and castors just three years later. Iberruedas's history is dotted with a series of milestones marking significant developments linked to continual innovation:

- in the products, with the aim of facilitating the work of load handling personnel in all companies and organisations;

Iberruedas SPA - Società Unipersonale - Via Quattro Passi 15, 41043 Formigine (MO) - Italy - P.IVA/VAT NUMBER IT00180900367 - Capitale Sociale € 3.640.000 i.v - R.E.A. MO nr. 65528 – Reg. Imprese MO nr. 00180900367 Italia: 059 410300-306, E-mail: comm.italia@tellurerota.com - Estero: +39 059 410302, E-mail: comm.estero@tellurerota.com - Fax: +39 059 572859