01

Nov

Technology applied to the sector of industrial wheels

Technology is the essence of all growth and competitiveness of any company. The sector of industrial wheels, where innovation leads to the constant creation of increasingly high performing models, is no exception.

Iberruedas has embraced these principles since 1953, the year in which it began to produce wheels and brackets for industrial, civil and domestic use. Today, production takes place in Formigine in 3 plants with a covered area of 15,000 sq.m. Every production stage uses skilled, qualified workers, up-to-date technologies and modern software to guarantee outstanding product quality. All this to achieve total customer satisfaction.

The most innovative and technologically advanced wheel models

The investments in research and development have enabled Iberruedas to design new products, studied by its internal, accredited laboratory TR Lab Test & Research, according to market requirements, to enable the company to stand out from the majority from its national and foreign competitors.

Below is a list of a examples of wheels and brackets for industrial use, which it has created using advanced technological processes.

- Steel sheet brackets and matching wheels

- Humidity and aggressive chemical resistant, stainless steel brackets

- Plastic wheels

- Polyurethane and Vulkollan® wheels

- Customised polyurethane wheels and castors

- Antistatic conductive wheels

- Non-marking wheels for delicate flooring

Click on the item to discover the technical specifications and details.

Steel sheet brackets and matching wheels

.jpg) Brackets for industrial wheels are of fundamental importance for the specifications and performance of the trolleys and other product types on which they are installed.

Brackets for industrial wheels are of fundamental importance for the specifications and performance of the trolleys and other product types on which they are installed.

The bracket connects the wheel to the trolley. All wheels normally require a bracket in order to be assembled on the trolley or equipment. Wheels with an axle integrated within the trolley are the sole exception.

Let’s begin with steel sheet brackets and components, produced with high tonnage, automatic, mechanical presses for pitch moulds.

Below is a brief description of the Iberruedas range of this type of brackets for innumerable industrial handling requirements. We advise you to always assess the load capacity of the overall wheel + bracket, which is restricted by the weaker element of the two (e.g.: if the wheel has a 500 kg loading capacity and is mounted on a bracket with a 300 kg loading capacity, the overall wheel + bracket has a loading capacity of 300 kg).

SL Brackets: for light loads (up to 130 kg) and infrequent manual handling. They are used with standard and thermoplastic rubber wheels.

NL Brackets: for medium and light loads (up to 300 kg) and even frequent manual handling. They are used with all Iberruedas wheels. A specific version is available for use at high temperatures and is normally used with resin wheels.

M Brackets: for medium loads (up to 500 kg) and even intense manual handling. They are used with TR and TR-Roll polyurethane wheels, Vulkollan® wheels, elastic rubber wheels, thermoplastic polyurethane wheels and polyamide wheels.

P Brackets: for heavy loads (up to 750 kg), intense manual and mechanical or mixed manual-mechanical handling with a maximum speed of up to 6 km/h and infrequent handling.

They are used with TR and TR-Roll polyurethane wheels, Vulkollan® wheels, elastic rubber wheels, thermoplastic polyurethane wheels, polyamide wheels, resin wheels and cast iron wheels.

PT Brackets: for heavy loads (up to 850 kg), intense manual and mechanical or mixed manual-mechanical handling with a maximum recommended speed of up to 6 km/h and even very frequent handling.

They are used with TR and TR-Roll polyurethane wheels, Vulkollan® wheels and elastic rubber wheels.

EP Brackets: for extra-heavy loads (up to 1000 kg), intense manual and mechanical or mixed manual-mechanical handling with a maximum recommended speed of up to 8 km/h and even very frequent handling.

They are used with TR and TR-Roll polyurethane wheels, Vulkollan® wheels and elastic rubber wheels.

Electrowelded and electrowelded twin brackets, models EE MHD, EEG MHD, EE HD, EEG HD, EE EHD: for very heavy loads (up to 3500 kg), for use even at high speeds (up to 16 km/h).

They are used with TR and TR-Roll polyurethane wheels, Vulkollan® wheels and elastic rubber wheels.

Electrowelded spring-loaded brackets models EES MHD: designed for use on trolleys moved by mechanised traction with a speed of up to 16 km/h, intended for internal and external transport, where there are obstacles and uneven flooring. They are used with TR and TR-Roll polyurethane wheels, Vulkollan® wheels and elastic rubber wheels.

Humidity and aggressive chemical resistant, stainless steel brackets

Iberruedas also offers a complete range of stainless steel brackets, developed in response to specific customer requirements e.g. humidity and aggressive chemical resistant, solutions required for food and chemical industries and, more generally speaking, where they need to be washed and sterilised frequently during the production process:

Iberruedas also offers a complete range of stainless steel brackets, developed in response to specific customer requirements e.g. humidity and aggressive chemical resistant, solutions required for food and chemical industries and, more generally speaking, where they need to be washed and sterilised frequently during the production process:

NLX Brackets: for medium and light loads (up to 300 kg) and even intense manual handling. A specific version is available for use at high temperatures and is normally used with resin wheels.

PX Brackets: for heavy loads (up to 750 kg), intense manual and mechanical or mixed manual-mechanical handling with a maximum speed of up to 6 km/h and infrequent handling.

The stainless steel brackets are used together with plastic wheels, most suited for use where there are humidity or aggressive chemicals.

Plastic wheels

Still on the topic of innovation, we would like to make a brief comment on the various models of wheels made of plastic materials. In this case, we are referring to polyamide (nylon), polypropylene, thermoplastic rubber and thermoplastic polyurethane wheels. All these wheels are produced with completely automated injection presses.

The highly automated processes guarantee Iberruedas thermoplastic and polyamide wheels are top performers and competitive in price.

Polyurethane and Vulkollan® wheels

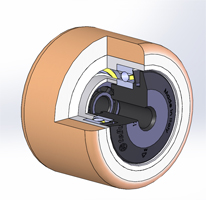

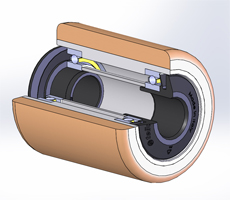

Iberruedas has designed and created a completely automatic production process for polyurethane wheels, which guarantees complete control over all the phases: from wheel centre and castor preparation to the preparation of the various polyurethane mixes, and including mould-on and oven-curing.

The TR and TR-Roll polyurethane wheels are manufactured with mixes studied in the TR Lab – Test & Research laboratory to guarantee the various applications have the best quality/price ratio and excellent performance.

The Vulkollan® wheels, on the other hand, are produced under Covestro licence, which establishes strict productive specifications in response to the most difficult loads and fastest handling speeds.

Customised polyurethane wheels

Nowadays, technology enables industrial wheels to be customised to a very high degree.

Iberruedas can offer dedicated, customised products with a polyurethane cover and modern lines, with its expert operators who take care of every detail requested by the customer to guarantee top quality and performance.

The TR Lab research and development laboratory has developed mixes of polyurethane, which fulfil various types of requests, such as the reduction of the rolling resistance, vibrations and noise, minimum maintenance, specific electrical conductivity and many more, calibrated to the direct requirements of the client companies.

Antistatic conductive wheels: safety for ESDs

The plastic materials, rubbers and elastomers used in the sector of industrial wheels are generally insulating and do not conduct electrical charge.

These materials do not, therefore, discharge to earth the electrical charge, which has accumulated on the machinery or trolley on which the wheels are mounted.

This accumulation of electrical charge can generate a charge, which could compromise the function of any electrically sensitive material transported on the trolley/machinery and trigger an explosion in environments at risk.

Wheels made using these materials can, therefore, prove unsuitable for potentially explosive environments and environments sensitive to electrostatic discharge

(ESDs).

Iberruedas offers customised solutions of wheels for ESDs, with modified, electrical specifications capable of fulfilling the requirements of various degrees of electrical conductivity:

Black rubber wheels with R <105 OHM (“conductive” according to the standard ISO 22883:2004).

Polyamide 6 wheels with R <105 OHM (“conductive” according to the standard ISO 22883:2004).

Polyurethane wheels with R<109 OHM

Upon the customer’s request, the TR and TR-Roll polyurethane covered wheels (series 62AL, 62ER, 62GH, 64, 65AL, 65GH, 65HT, 65ER) can have an adequately modified polyurethane cover to give an electrical resistance specification of <109 Ohm.

Non-marking wheels for delicate flooring

Delicate floors, which need to be protected and cleaned regularly, are seen increasingly in industry today. This is especially frequent in environments requiring high levels of hygiene, such as the food and pharmaceutical industries.

Trolleys, which do not mark or stain the floor, are of fundamental importance here.

Iberruedas offers non-marking, non-staining wheels for different types of industrial use:

- For light loads: grey standard and thermoplastic rubber wheels.

- For medium loads: thermoplastic polyurethane and non-marking blue elastic rubber wheels.

- For heavy loads and mechanical handling: TR-Roll polyurethane wheels.

- For high temperatures: non-staining silicone rubber wheels.

Lean production methods at the service of the customer

Iberruedas organises its production processes according to the principles of Lean production,, which aims to minimise waste and, at the same time, guarantees extremely reliable delivery times, thanks to a very flexible service.

The combination of Lean production and traceability of each stage via the Management Information System offers customers a considerable degree of flexibility in production quantities, product marking and packaging, without compromising rapid delivery.