04

Feb

Industrial wheels: selection criteria for light, medium and heavy duty loads

Selection criteria, such as wheels, are to be selected depending on various parameters: first of all the type of use and load they will have to bear.

Contents of the article

- Industrial wheels and brackets

- Loading capacity calculation for industrial wheels depending on speed

- Industrial wheels for light duty loads

- Industrial wheels for medium duty loads

- Industrial wheels for heavy duty loads

Industrial wheels and brackets

When dealing with industrial wheels and their selection criteria it is necessary to consider the correct information to match the most suitable brackets.

When dealing with industrial wheels and their selection criteria it is necessary to consider the correct information to match the most suitable brackets.

Depending on the industrial environment where wheels are used, the specific application and the structure of the trolley or of the equipment, different kind of wheels and castors may be used : swivel castors, fixed castors, swivel castor with brake for example.

The main feature is that swivel castors can move in different directions, while fixed ones are locked in one direction only. Therefore, it is better to choose fixed castors for straight paths, while in case of frequent changes of directions it is advisable to choose swivel castors.

There are many types of bracket fittings, the most common are: square or rectangular top plate with 4 or 2 holes, with bolt hole , stems, expanders as well as pin clips. The choice between one of these mainly depends on the type of trolley or equipment where they are to be fitted.

Loading capacity calculation for industrial wheels depending on speed

The loading capacity for one wheel is calculated by considering the load weight it will have to transport plus the tare of the trolley itself.

The following pieces of information must be kept in mind when calculating the loading capacity:

For a 4-wheel trolley:

Capacity = (solid load weight + trolley tare weight)/3

Capacity = (liquid load weight + trolley tare weight)/2

Dividing by 2 or 3, even in case of a 4-wheel trolley depends on the fact that not all 4 wheels are always in contact with the floor.

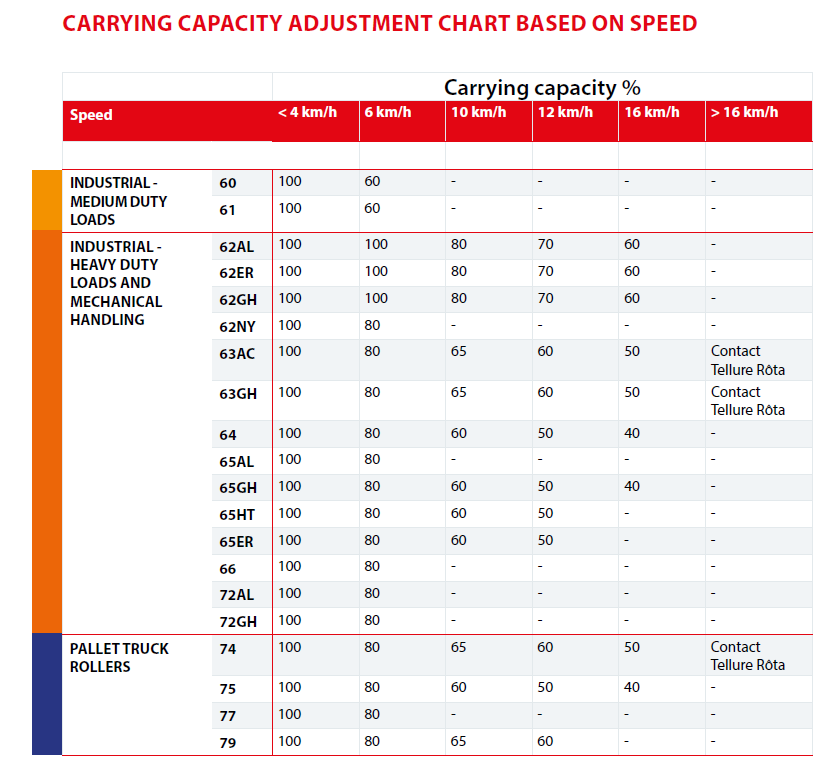

Furthermore, the handling speed should be considered and especially the reduction of the loading capacity as the speed increases. The following chart could come in handy when choosing the most suitable Iberruedas product:

|

Industrial wheels for light duty loads

Iberruedas wheels for light duty industrial wheels are perfect for manual handling of trolleys with total loads up to 150-200 kg.

The loading capacity of each wheel is higher (up to 300 kg each wheel), so that it can easily bear temporary overloads, but for frequent handling needs such wheels are intended for trolleys for total loads as above mentioned (150-200 kg).

These wheels usually feature a standard, thermoplastic or pneumatic, grey or black rubber coating. For delicate flooring grey rubber is recommended, as it is non-marking. For mixed usages on indoor-outdoor floors, the use of standard or pneumatic rubber is recommended.

For sandy floors, the only suitable wheels are pneumatic wheels.

The wheels in this category are combined with Iberruedas SL and NL type brackets (light duty load), with bolt hole fitting; grey thermoplastic rubber wheels and grey standard rubber wheels with polypropylene centre series 71 and 22 are also combined with stainless steel NLX type brackets.

These wheels can be used in all industrial environments and, in some cases, also in domestic and institutional context (especially series 71).

Some examples of typical applications: tool trolleys, luggage trolleys, stairs, small mobile scaffoldings, cassette trolleys, waste bin containers. Wheels series 71 are also recommended for “lean production” tubular trolleys, mainly combined with Zamak stem.

Industrial wheels for medium duty loads

Iberruedas wheels for medium duty load industrial trolleys are perfect for manual handling of trolleys with total loading capacity up to 500 kg. Each wheel features higher loading capacities (up to 700 kg each wheel), so that it can adequately bear any temporary overload, but for frequent handling they are suggested for trolleys with total loading capacities of maximum 400 kg.

They are combined with Iberruedas light duty load (NL) brackets, stainless steel light duty load (NLX) brackets, medium duty load (M) brackets, and in some series also with Heavy (P) duty load and stainless steel Heavy (PX) duty load brackets.

This category includes polyamide 6 solid wheels, thermoplastic polyurethane coated wheels (a harder version with 55 Shore D hardness and a softer version with 85 Shore A hardness), and non-marking blue elastic rubber wheels.

Polyamide 6 solid wheels feature excellent rolling capacity and resistance to aggressive chemical agents and moisture, but they are only intended to be used on smooth, compact, and resistant floors. They cannot be used on delicate floors or in case of obstacles.

Generally, they are used for indoor industrial trolleys in the food and canning industry, in the chemical industry, for tannery equipment, on flower trolleys, manual pallet trucks and, combined with suitable brackets, on mobile scaffoldings.

Thermoplastic polyurethane wheels offer resistance features which are similar to those featured by polyamide 6 wheels but with a lower hardness, and therefore they can also be used on delicate surfaces. The softer polyurethane version (85 Shore A, series 61) is also suitable in case of minor obstacles on the path. The version featuring the hub with ball bearings is especially suitable in case of frequently handled trolleys.

They are suitable to be used in the food and canning industry, in chemical industries, on mobile scaffoldings, and generally for different indoor industrial use. They are also recommended for “lean production” tubular trolleys, mainly combined with Zamak stem.

Elastic rubber wheels are especially suitable to be used on uneven floors with obstacles. Typical applications: indoor and outdoor industrial trolleys, manual pallet trucks, waste bin containers, flight-cases to carry musical instruments.

Industrial wheels for heavy duty loads

Iberruedas heavy duty load wheels are intended to be used for total loads higher than 500 kg, or for lower loading capacity trolleys, only in case they are not manually handled by operators but towed by mechanical equipment. The loading capacity of these wheels can be up to 4300 kg each wheel, however, even customised versions on customer’s request may be implemented, even for higher loading capacities.

Handling trolleys with total loading capacities higher than 500 kg involves specific features. In fact, in such conditions, it is really important to choose the right wheel, as any wrong choice may easily involve breaking the equipment where the wheel is assembled. In case of a heavy load this may involve stopping the production lines, overstress the operators and also produce safety risks in workplaces.

As for all types of wheels, also for heavy duty wheels it is important to consider the floor, the environment conditions, the nature and type of load to be handled.

For high loads it is very important to consider the handling speed and the type of traction vehicle which will handle the equipment where the wheels are assembled.

Handling speed is a key factor in choosing the right wheel.

For zero speed and therefore mainly static use, comparing the necessary load for each wheel with the static load mentioned in Iberruedas catalogue is enough. In case of heavy loads for mainly static use, polyamide wheels for high loading capacity and metal wheels (steel or mechanical engineering cast iron) are recommended.

Types of suggested wheels

Series 69 - Cast iron solid wheels

Series 68 P - Polyamide 6 solid wheels for heavy loads

If speed is not 0, and therefore the equipment is intended for frequent handling, it is necessary to consider the traction vehicle: manual handling, with towed mechanical equipment or motorised equipment.

If speed is not 0, and therefore the equipment is intended for frequent handling, it is necessary to consider the traction vehicle: manual handling, with towed mechanical equipment or motorised equipment.

Handling is manual when the force is applied by one or more people and speed is usually equal to or lower than 4 km/h.

Handling is instead mechanical when the force is applied by a mechanical vehicle and speed is greater than 4 km/h.

In case of manual handling, the key factor to be considered is the rolling resistance.

Technically speaking, rolling resistance is the value (expressed in daN) of the maximum load which can be borne by each wheel at the constant speed of 4 km/h with the application of a traction or pushing force equal to 5 daN (not including start-up force). This value is calculated by applying a traction force equal to 20 daN to a 4-wheel trolley and measuring the maximum loading capacity for each wheel during handling at normal speed.

The applied traction force, which is 20 daN, is compliant with international labour rules for indoor handling and it is widely recognised as the limit effort that a human being can bear for long periods.

Generally, the higher the rolling resistance of the wheel, the lower the effort necessary for the operator to handle the trolley, and therefore the trolley is more ergonomic.

Iberruedas "TR" polyurethane and "TR-Roll" Vulkollan® coated wheels series 62BS, 62AL, 62NY, 62ER, 62GH, 63AC, 64, 65AL, 65GH and 65ER are the best rolling heavy duty wheels. Depending on floor, the chemical aggressive agents and the working cycles, one or the other type of the suggested series will be more suitable.

Types of suggested wheels

Series 62 ST - "TR-Roll" polyurethane wheels, aluminium centre

Series 62 ER - "TR-Roll" polyurethane wheels with ergonomic round profile, aluminium centre

Series 62 GH - "TR-Roll" polyurethane wheels, mechanical engineering cast iron centre

Series 62 NY - "TR-Roll" polyurethane wheels, polyamide 6 centre

Series 63 ST - Vulkollan® wheels, steel centre

Series 63 GH - Vulkollan® wheels, mechanical engineering cast-iron centre

Series 64 ST - "TR" polyurethane wheels, mechanical engineering cast iron centre

Series 65 AL - "TR" polyurethane wheels, aluminium centre

Series 65 GH - "TR" polyurethane wheels, mechanical engineering cast iron centre

Series 65 HT - "TR" polyurethane wheels high thickness, aluminium centre

Series 65 ER - "TR" polyurethane wheels with ergonomic round profile, aluminium centre

Rolling resistance is an indicative value of the handling effort at constant speed. The necessary effort to move a standstill trolley is higher. In order to reduce it, it is recommended to use wheels with ergonomic round profile (series 62ER and 65ER).

Types of suggested wheels

Series 65 ER - "TR" polyurethane wheels with ergonomic round profile, aluminium centre

Series 62 ER - "TR-Roll" polyurethane wheels with ergonomic round profile, aluminium centre

For mechanical handling only polyurethane coated wheels with hub with ball bearings are suitable. Furthermore, in case the handling speed is greater than 6 km/h only wheels with metal centre (aluminium, mechanical engineering cast iron, steel) can be used. Therefore plastic centre wheels must be excluded.

Types of suggested wheels

Series 62 ST - "TR-Roll" polyurethane wheels, aluminium centre

Series 62 ER - "TR-Roll" polyurethane wheels with ergonomic round profile, aluminium centre

Series 62 GH - "TR-Roll" polyurethane wheels, mechanical engineering cast iron centre

Series 63 ST - Vulkollan® wheels, steel centre

Series 63 GH - Vulkollan® wheels, mechanical engineering cast-iron centre

Series 64 ST - "TR" polyurethane wheels, mechanical engineering cast iron centre

Series 65 HT - "TR" polyurethane wheels high thickness, aluminium centre

Series 65 ER - "TR" polyurethane wheels with ergonomic round profile, aluminium centre

For speeds greater than 12 km/h, it is strongly suggested to use elastic polyurethane or Vulkollan® coated and high thickness wheels.

Types of suggested wheels

Series 62 ST - "TR-Roll" polyurethane wheels, aluminium centre

Series 62 ER - "TR-Roll" polyurethane wheels with ergonomic round profile, aluminium centre

Series 62 GH - "TR-Roll" polyurethane wheels, mechanical engineering cast iron centre

Series 63 ST - Vulkollan® wheels, steel centre

Series 63 GH - Vulkollan® wheels, mechanical engineering cast-iron centre

Heavy duty brackets

It is also particularly important to consider the right bracket to be combined with the wheels, as not all the brackets are able to withstand shocks and stresses related to mechanical handling.

For mechanical handling at high speed Heavy duty load PT brackets with hardened ball race grooves (up to 6 km/h), Extra heavy duty load EP brackets (up to 6 km/h), electrowelded brackets and electrowelded sprung-loaded brackets (up to 16 km/h) are recommended.

For speeds greater than 16 km/h, it is necessary to contact Iberruedas for a dedicated consultation.

In motorised trolleys (trolleys with drive wheels - self-propelled trolleys) wheels are subjected to special stress.

The drive wheels, in fact, in addition to bearing the load, must allow the transmission of the tangential force, which allows the movement of the wheel and thus of the trolley. In addition, the coating of drive wheels is subjected to greater stress.

In particular, when choosing wheels and brackets for self-propelled trolleys, the following elements must be carefully considered:

• type of bushing or bearing applied in the hub;

• hub/shaft coupling tolerances;

• hub material with respect to shaft material;

• frequency of starts and stops of the motion transmission component;

• reversal of the direction of motion;

• presence of - even temporary - overloads.

As there are many factors to be considered, it is recommended to contact directly Iberruedas to choose wheels and brackets to be assembled on self-propelled trolleys.

Type of suggested wheels

Series 64 ST - "TR" polyurethane wheels, mechanical engineering cast iron centre

Conclusions

As explained above, there are many kind of wheels.

The first principle to be considered, beyond the various elements, is the safety factor: a wheel which is not suitable to bear a certain load may involve risks for the operators as well as for the transported load. Otherwise, in case a wheel conceived for heavy duty loads is under-used, it becomes poorly efficient with regards to its rolling capacity.

The right criterion for choosing a wheel involves obtaining all necessary information on the actual conditions it is going to be used under.