28

Sep

Industrial wheels: the perfect answers for every requirement

The market offers a vast range of industrial castors to move machines and trolleys for every sector, with specifications more or less suitable for the specific application and environment, in which they have to work.

On the basis of these (and other) parameters, client companies are able to choose the most suitable wheels for their vehicles in order to achieve maximum efficiency and safety for the operator in the short, medium and long term.

Which features do you always have to check to ensure maximum efficiency from your vehicles?

The 4 factors to bear in mind when you select industrial wheels

You need, therefore, to examine a series of elements, ranging from ease of movement to the safety of the trolley or other type of machinery.

Below are the 4 key factors to consider when you select castors for trolleys:

1. Flooring type and conditions: in practice, the floor on which the trolley will have to move;

2. Environment of use: in this case you need to take into account any aggressive chemicals, normal or extreme operational humidity and temperature;

3. Load amount and type: this specifically refers to the overall weight the trolley will have to bear, the type of load (solid or liquid) and the trolley tare weight. All these elements determine the minimum loading capacity the trolley must have to guarantee safe movement;

4. Means of traction and speed: You need to select specific wheel types according to the type of movement (which can be manual or mechanical) and speed of the trolley, and reject those which are unsuitable for the purpose.

The optimum choice in terms of cost is, therefore, the one which is designed to fulfil specific purposes.

Industrial wheels classified according to price

The cost of industrial wheels depends on various factors (production technologies, construction materials, distribution procedures, performance, etc.). Thus, every possible classification according to the end price should be considered merely a guide.

You need to pay maximum attention to your specific application requirements, as a better performing, more hard-wearing and more expensive wheel often means you save in the medium and long term, as it lasts longer, needs to be changed less frequently and protects the equipment on which it is assembled better.

Given these pertinent observations, here is the general classification, from the most expensive to the most economical industrial wheels:

- Vulkollan® wheels®

- TR polyurethane wheels

- Steel and cast iron wheels

- Silicone rubber wheels

- Thermoplastic polyurethane wheels

- Resin wheels

- Polyamide 6 wheels

- Rubber wheels

Click on the wheel type to discover the technical specifications, in which sectors they are used and their maximum load capacity.

Rubber Wheels

The rubber used to construct wheels for industrial use can be vulcanised or injection moulded.

In the first case, the rubber is admixed with suitable mineral loads and vulcanising agents and subjected to a process known as “vulcanisation”. Via this process, the molecular structure of the rubber is substantially modified: from a “doughy” material at the beginning of the process, it becomes a product which is no longer fusible and maintains the shape of the mould, in which the reaction occurs. The ring obtained in this way is assembled on to the wheel centre mechanically or with adhesive. Vulcanised rubber has significant, elastic deformability properties within a relatively wide range of loads applied under traction and compression.

In the second case, the rubber is subjected to processes of chemical synthesis. The material obtained in this way is injected into a mould, which already contains the wheel centre. The injected rubber maintains its fusibility even after moulding.

The different types of rubber used and the different methods to apply the covering to the centre divides Iberruedas wheels into: standard, elastic, silicone and thermoplastic.

The main feature of rubber wheels is their excellent elasticity. So let’s analyse the surface factor: rubber wheels are suitable for various flooring types, for mixed internal-external use, including on uneven, bumpy surfaces.

They can withstand oils and substances normally found in industrial environments. However, they are unsuitable where highly aggressive chemical agents are present.

Rubber wheels are generally suitable for medium-light loads: more specifically, those made of standard and thermoplastic rubber for light loads, whereas those made of elastic rubber are for medium loads.

Rubber wheels are also available in a non-marking, conductive version.

Examples of applications

The fields of application vary considerably. Standard rubber wheels (grey or black, series 22, 23, 52, 53) can be used for luggage trolleys, tool trolleys, small mobile scaffolding, waste bins, trolleys for handling goods inside workshops and small industries.

Thermoplastic rubber wheels (series 71) are recommended mainly for internal use, e.g. luggage trolleys, tool trolleys, institutional and catering trolleys, trolleys for indoor industrial use, tubular and lean trolleys.

On the other hand, elastic rubber wheels (series 72AL, 72GH, 73, 73AE) exploit their greater elasticity on uneven flooring. They are also ideal for medium loads, manual transpallets, transport cases for musical instruments, or for mechanical handling up to 6 km/h, e.g. internal and external industrial handling and waste bins.

Maximum load capacity

230 kg/wheel for standard and thermoplastic rubber wheels.

500 kg/wheel for elastic rubber wheels.

RUBBER WHEELS DEVELOPED BY Iberruedas

Polyamide 6 wheels

Polyamides (PA) are long-chain polymers containing amidic units. Their main features are: a relatively low specific weight, shock and wear and tear resistant, discreet electrical insulation, solvent, oil, fat and fuel resistant. Their excellent price/performance ratio makes polyamides the most commonly used polymers in industry.

Iberruedas produces polyamide 6 (or nylon 6) monolithic wheels, obtained by injection moulding of natural polyamide 6.

Polyamide 6 wheels are recommended for mainly static use. Their smooth movement guarantees minimum effort for manual handling, but only on smooth flooring: their exceptional hardness actually makes them unsuitable on delicate or uneven flooring.

They have a good load capacity and are, therefore, suitable for medium loads. However, we also have special solutions in polyamide for heavy and extremely heavy loads.

An additional strong point is their excellent resistance to aggressive chemicals and humidity and they are recommended for use in chemical and food industries.

Examples of applications

Trolleys for internal handling in food and food processing industries, flower trolleys, manual transpallets, mobile scaffolding.

Maximum load capacity

700 kg/wheel.

POLYAMIDE 6 WHEELS DEVELOPED BY Iberruedas

Thermoplastic polyurethane wheels

Thermoplastic polyurethane (TPU – Thermoplastic Polyurethane) is a plastic polyurethane (insert link below, polyurethane) with many properties, including elasticity and resistance to oil, fat and abrasion.

Iberruedas transforms two different types of thermoplastic polyurethane, which differ in hardness: TPU 85A and TPU 55D.

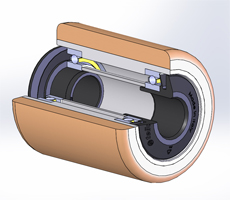

The Iberruedas thermoplastic polyurethane wheel centres are made of polyamide 6.

These wheels are injection moulded with completely automated injection presses.

Thermoplastic Polyurethane wheels are smooth running, long-lasting and resistant to aggressive chemicals and humidity, so they are ideal for internal use and suitable to be washed and sterilised frequently. They offer a versatile, ideal solution in various industrial and institutional sectors, even on delicate and slightly bumpy floors. We recommend the version with ball bearings for continual handling of medium loads. The ball bearings are protected from dust and dirt, so the wheels of this version can also be washed and are suitable for environments, where hygiene is of the utmost importance.

Examples of applications

Trolleys for industrial use, tubular trolleys, trolleys for the food and chemical industries, mobile scaffolding.

Maximum load capacity

450 kg/wheel.

THERMOPLASTIC POLYURETHANE WHEELS DEVELOPED BY Iberruedas

Polyurethane wheels

Polyurethane is a polymer which, compared to traditional rubber, is more resistant and longer lasting, guarantees enhanced smooth running and can be more easily customised according to specific user requirements.

Overall, the quality/price ratio is more favourable compared to rubber.

Iberruedas offers three standard polyurethane mixes:

• “TR” polyurethane

• “TR-Roll” polyurethane

• Vulkollan®

Each mix features a series of mechanical parameters, which the researchers in the “Test & Research” laboratory are able to modify in order to best adapt the wheel for each specific use.

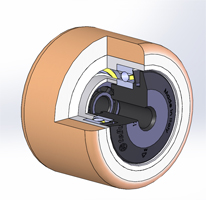

Iberruedas has designed and created a completely automatic production process for polyurethane wheels, which guarantees complete control over all the phases: centre preparation, preparation of the various polyurethane mixes, mould-on and oven-curing.

“TR” POLYURETHANE

Its excellent physical and mechanical properties ensure this polyurethane is extremely wear, tear and deformation-resistant. It is especially recommended for applications, which put strong stresses on the tread with speeds of up to 12 km/h.

It has a thick covering and can be used on bumpy surfaces.

“TR-ROLL” ELASTIC POLYURETHANE

An innovative product, it blends the load capacity and resistance to wear and tear of polyurethane with the ability to overcome obstacles, silent running and dampened vibrations and shocks by the elastic rubber. It is extremely smooth running and makes it easier for the operator to handle the equipment. Excellent performance with high speeds and conveyor applications.

If matched with suitable brackets, they guarantee excellent performance for mechanical handling up to 16 km/h.

The solutions with an ergonomic, rounded profile in both TR polyurethane and TR-Roll polyurethane reduce the strength required for manual handling of the trolley, especially in the initial acceleration.

Examples of applications

Trolleys for internal industrial handling, AGV trolleys, containers, electric transpallets, fork-lift trucks, trolleys for the automobile industry.

Maximum load capacity

3500 kg/wheel.

TR AND TR-ROLL POLYURETHANE WHEELS DEVELOPED BY Iberruedas

Vulkollan® wheels (Covestro licence)

Vulkollan® is a polyurethane-based elastomer (link a poliuretano), with excellent properties of elasticity, high breaking loads, an excellent elastic range, high ultimate elongation even at maximum hardness, and high abrasion resistance.

Vulkollan® wheels, produced by Iberruedas according to rigid licensing specifications, feature excellent load capacity and are highly shock, wear and tear-resistant.

This is why they provide the most suitable solutions for applications under onerous conditions and continual use.

If matched with suitable brackets, they are perfect for mechanical handling at high speeds (up to 16 km/h).

Examples of applications

Trolleys for internal industrial handling, AGV trolleys, containers, electric transpallets, fork-lift trucks.

Maximum load capacity

3500 kg/wheel.

VULKOLLAN® WHEELS; DEVELOPED BY Iberruedas

Resin wheels

Phenolic resins belong to a family of polymers, which includes Bakelite, considered to be the first, synthetic, plastic material in the world.

They are usually thermosetting materials, i.e. they cannot be moulded further after the initial moulding, as they have a reticular structure.

The Iberruedas monolithic, thermosetting resin wheels are produced by compression moulding a mixture of asbestos-free, phenolic resins, opportunely charged with inert material, and subsequently oven-cured.

Examples of applications

Thanks to their high temperature resistance (up to +300°C), resin wheels are particularly suitable for use in cooking ovens, especially for bakeries.

Their exceptional hardness, however, makes them unsuitable on uneven or bumpy flooring.

The version with ball bearings guarantees excellent performance without squeaking, even under prolonged use with heavy loads.

They are assembled on specific brackets and axles to withstand high temperatures.

Maximum load capacity

500 kg/wheel.

RESIN WHEELS DEVELOPED BY Iberruedas

Silicone rubber wheels

Silicone rubber is an innovative solution: it is a stable material with high elasticity and mechanical strength.

The silicone rubber used for Iberruedas wheels is produced via a process of hot vulcanisation.

Examples of applications

Silicone rubber wheels show good resistance at low and high temperatures (from -30 to +250 °C), and are recommended for cooking ovens and bakeries, like the resin wheels.

Unlike the first, however, silicone rubber wheels can overcome obstacles on uneven flooring and, at the same time, reduce noise levels during use thanks to their elasticity.

They are assembled on specific brackets and axles to withstand high temperatures.

Maximum load capacity

100 kg/wheel.

SILICONE RUBBER WHEELS DEVELOPED BY Iberruedas

Engineering cast iron and steel wheels

Cast iron is an iron-carbon alloy (or ferrous alloy) with a relatively high carbon content (2.06% < C < 6.67%, which is the saturation limit) obtained by reducing or by heat treating iron minerals.

Monolithic, engineering cast iron wheels are produced by the mould-on of cast iron EN-GJL-200 and subsequently painted green.

Steel is the name given to an alloy consisting mainly of iron and carbon, where the percentage of the latter does not exceed 2.06%; beyond that limit the properties of the material change and the alloy takes the name of cast iron.

Steel and engineering cast iron wheels have an excellent load capacity on the one hand, but on the other, they can easily damage flooring.

They are, therefore, recommended mainly for static applications or for occasional handling.

The version with a bore with bushing hole is particularly resistant to temperatures ranging from-40°C to +400°C. These wheels are recommended for use in cooking ovens, but only if assembled on specific brackets for high temperatures.

Examples of applications

Trolleys for mechanical workshops, industrial ovens.

Maximum load capacity

1000 kg/wheel.

ENGENEERING CAST IRON AND STEEL WHEELS DEVELOPED BY Iberruedas

When the result is guaranteed

There are numerous combinations of wheels and castors and practical requirements dictated by the type of flooring, handling, speed, safety, temperatures of usage, load, the presence of aggressive or corrosive elements, production improvement and additional factors.

To enable the best performance for each vehicle, Iberruedas continues to study and research new materials and customised applications.

For more details on the most suitable technological solutions for your business, get in touch with our specialists here:: Contact the specialists of Iberruedas.