17

Dec

Industrial wheels of the future: what to expect from technological research

Contents

-

Introduction

-

The research behind Iberruedas's industrial wheels

-

Attention to industry 4.0 requirements and to the Lean Production principles

-

New wheels and castors for AGV (Automated Guided Vehicle)

-

Further research for designing practical and innovative solutions

Introduction

What to expect from the industrial wheels of the future? What are the materials under investigation? For which types of applications? What are the evolution trends in the sector? Many questions arise about the current situation in this field. That's why it may be useful to examine in depth these topics, addressing the strategies that the main manufacturers are implementing.

The research behind Iberruedas's industrial wheels

We believe it is right to start at home, considering that Iberruedas is one of the manufacturers most attentive to the research and development of new solutions in the field of industrial wheels and their castors.

The research is in the hands of the internal laboratory TR Lab Test & Research, a scientific structure in the industrial context, accredited since 2011 by the Emilia-Romagna High Technology Network, with operational autonomy but in close contact with the production departments.

The Emilia-Romagna High Technology Network consists of industrial research laboratories and centres for innovation. It brings together academic institutions and public and private research centres in the region to offer expertise, equipment and resources to the production system. Being part of a network of excellence allows TRLab laboratory to constantly update and expand its knowledge for providing customers with cutting-edge services and solutions.

Iberruedas's Test & Research Laboratory is equipped with machinery and instrumentation for testing materials, components and finished products. All instruments are subject to maintenance programs and periodic calibration checks, with the intervention of laboratories and calibration facilities certified SIT with a periodicity between 12 and 18 months.

All this enables us to guarantee high quality innovating solutions as well as offering consulting services, focused on:

- identification, development and characterization of polyurethane compounds and plastic materials;

- study of components in metallic materials for manufacturing castors with optimised performances.

Attention to industry 4.0 requirements and to the Lean Production principles

The search for new handling solutions is developed taking into account the continuously evolving needs arising from the industry 4.0. We refer to the industry model organized according to the principles of automation, able to integrate new production technologies in order to improve working conditions, create new business models and increase the output and quality of production facilities.

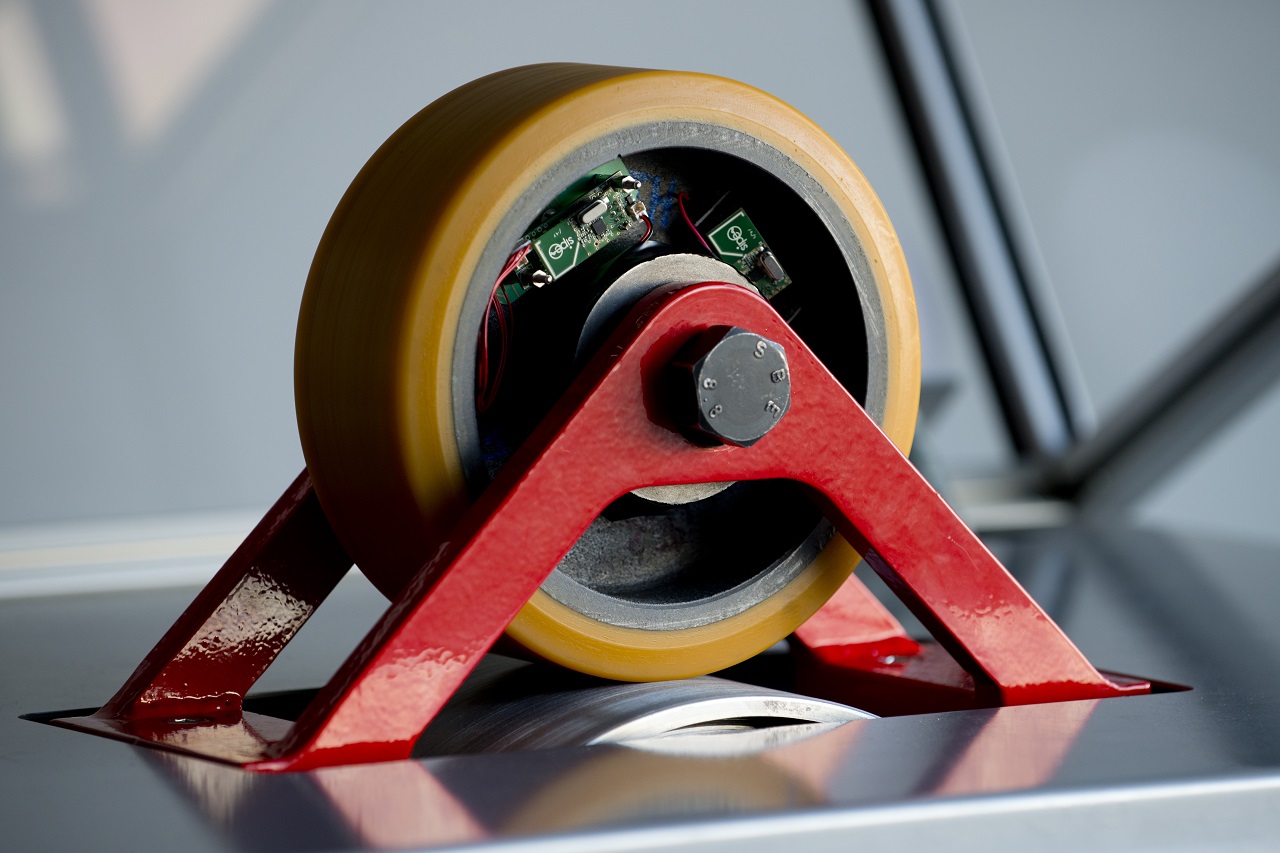

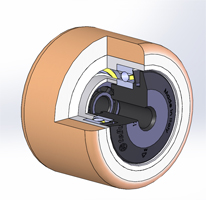

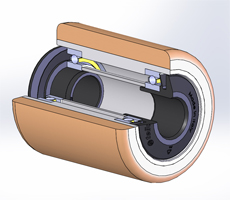

In the context of Industry 4.0, IOT needs continuous efficiency in production environments. The TRLab laboratory is developing the "SensorizedWheel, the Intelligent Wheel" project.

The aim of the project is to allow the user of the trolley to have real-time information for monitoring the operating state of the wheel, thus avoid using it in sub-optimal conditions.

In this way, it is possible to preserve the performance of the wheel and the trolley over time.

With this target, TRLab has developed a sensor system for polyurethane wheels used for mechanical handling, capable of monitoring the current and cumulative operating state of the wheel and transmitting data via Wi-Fi.

The monitoring system implemented includes a check of the following parameters:

• temperature

• tread stress due to load

• speed

• number of rotations carried out

• wear (indirect measurement given the stress and the number of rotations carried out)

The user of the wheel receives instantaneous and cumulative alarms via Wi-Fi on his/her computer, when the warranty performances are exceeded.

SensorizedWheel is a patented project; as regards its launching state in the market, it is currently being prototyped.

Innovation involves not only products, but also processes. In fact modern industry requires fast services, flexibility and efficiency.

Iberruedas's production processes follow the principles of Lean Production, aiming at minimizing waste and, at the same time, guaranteeing to the customer high delivery reliability, thanks to the service flexibility.

The combination of Lean production and step traceability through Iberruedas's Management Information System offers customers a high degree of flexibility in production quantities, product labelling and packaging, without affecting delivery timeliness.

New wheels and castors for AGV (Automated Guided Vehicle)

If we look at it from a more practical standpoint, research and development are, as mentioned, addressing the new business needs, within the different sectors.

Some studies in Tellure Rota’s lab are analysing a new range of polyurethane products, with specific solutions for high-speed use on the latest generation of industrial vehicles. Here are some examples.

Within the industry, so-called collaborative robots are increasingly used to automate various production processes.

These qualities allow the use of artificial intelligence to improve at the same time the internal logistics operations of companies or their warehouses.

This is leading to a large number of automatic trolleys. The AGVs (Automated Guided Vehicles), consist of machines that can move independently in the work spaces without requiring personnel on board, by using intelligent management software. In order to be able to move, the AGVs follow magnetic stripes, coloured lines or other markers used as a reference along the route.

LGVs (Laser Guided Vehicles), on the other hand, are a sub-family of the AVGs, and are their most advanced members. In this case, handling depends on laser scanners that provide a complete mapping of the work area, without requiring indicators to travel the route.

These new machines eliminate strenuous personnel travel, as well as time loss associated with low value-added activities. Another advantage of AGV and IGV with automated driving systems is the delivery of the right quantity of material at the precise moment when it is needed, thus avoiding accumulation on production lines and ensuring effective stock management.

These new machines must be equipped with the best performing wheels, such as the coated solutions with polyurethane compounds by Iberruedas.

Further research for designing practical and innovative solutions

The above new wheel and castor features is not all there is to it. The TR Lab Test & Research is working on many other solutions that can facilitate the tasks of operators who daily use handling equipment based on industrial wheels.

One of these areas of research focuses on the development of new materials characterised by modified electrical resistance. This is in order to expand the offer of antistatic and electrically conductive solutions, suitable to be used in explosive or sensitive ESD environments, knowing how important is the prevention of safety in the workplace.

Other projects include:

- New high-performance polyurethane compounds;

- Expanding the range of stainless steel castors, to provide increasingly specific solutions for humid environments and in the presence of potentially aggressive chemicals;

- Broadening the range of drive wheels, made of "TR" polyurethane and "TR-Roll" polyurethane:

- Widening the range of "TR" polyurethane rollers with labyrinths for electric pallet trucks.

Do you want to know more about all the ranges of industrial wheels and castors, and the possibility of customising them for special needs? Contact our experts to get a no-obligation consultation about your project.