08

Jan

The evolution of industrial wheels over the centuries

Contents

-

Introduction

-

The dawn of the wheel

-

The first rudimentary engineering works on wheels

-

The evolution of industrial wheels

-

The Second Industrial Revolution (second half of the 19th century)

-

The developments of the 20th century

-

Verification tests and safety standards for industrial wheels

-

Most suitable industrial wheels in relation to the actual use

Introduction

It seems interesting to take not one, but several steps back to analyse what has been the contribution of the industrial world to wheels for professional use and how these processes have evolved over the centuries.

The dawn of the wheel

The wheel consists of a circular mechanical organ, revolving around an axis passing through the centre. The invention of this element has undoubtedly been a historical moment of great importance for land transport. The wheel allowed man to transfer heavy objects, freeing him from the need to carry the load on himself or on animals.

According to studies, the discovery of the wheel dates back to the time of the Mesopotamian civilization (which began around the fourth millennium B.C.), with particular reference to Central Asian populations, with developments and applications involving Chinese people. It also seems that it was not known in sub-Saharan Africa and Australia before contacts with the rest of the world began.

The first wheels were portions of a disc-shaped tree trunk with parallel faces, fixed to the two ends of an axis by means of wooden wedges.

The lighter spoked wheels at first consisted of only four spokes, which later became six and then eight. In Tehran, at the National Museum of Iran, a 12-spoke wheel dating from 2000 B.C. is on display.

A thousand years later (about 1000 B.C.) the need to reduce excessive wear on the peripheral part of the wheel prompted the Celts to look for suitable protection systems.

The first rudimentary engineering works on wheels

Around 300 B.C., the first method for strengthening the wheels and allowing them to be used for an acceptable period of time was to use wide-headed nails stuck into the tread, one next to the other, so as to form a wear-resistant metal band; in a second stage, the wheels were completely rimmed with an iron ring.

The following centuries alternated periods of progress and stagnation, depending on the different cultures and their knowledge of materials.

A decisive step forward was taken at the end of the 1800s, when the cast wheel was introduced and manufactured on an industrial scale. Moving closer to the present day, at the beginning of the 20th century the first cast wheel with vulcanised rubber coating was made.

When the first mechanically driven vehicles arrived on the market and the metallurgical industry started to develop side-by-side, in addition to the enormous progress achieved due to wartime conflicts, the wheel itself also evolved in line with these new vehicles.

Hence the origin of the castor (around 1930), a fundamental component for the modern use of the wheel, which led to its greater application for various domestic uses.

The evolution of industrial wheels

Let's start with a particularly important assumption in relation to wheels for industrial use: the industrial castor was created as an indispensable element for the manual handling of trolleys for particularly heavy loads. Therefore the castor appeared at the beginning of the First Industrial Revolution (1760-1780) in the textile-metallurgical sector, thanks to the introduction of the flying shuttle and the steam engine.

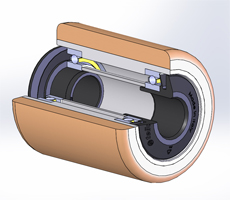

Despite the exponential increase in production volumes, the metal wheel (cast iron or iron), placed under more or less special structures, could still satisfy the needs of the time. The ball bearing had not yet been invented and the hub had a through-hole.

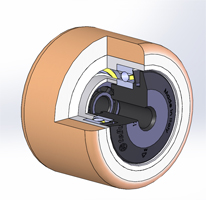

Thanks to the French invention of the ball bearing for bicycles, the industrial castor took decisive evolutionary steps with the first production of wheels fitting ball and roller bearings.

The Second Industrial Revolution (second half of the 19th century)

The Second Industrial Revolution, that took place between 1870 and 1880, coincided with the introduction of electricity, chemicals and oil.

In the field of industrial wheels, the main developments in those years involved the discovery of vulcanized rubber by Charles Goodyear.

Vulcanization consisted in the ability of rubber latex to combine with sulphur at high temperatures and transform itself into a product with mechanical and physical properties superior to those of raw rubber.

From here on, industrial wheels were either made of metal or covered with a rubber tread, with through-hole hub and ball or roller bearing. Naturally, this new feature widened the range of applications, allowing for greater ease of movement on smooth surfaces. Economic growth increased the need to equip machines and trolleys with wheels for their handling.

The developments of the 20th century

The developments of the 20th century

With the beginning of the 1900s, after the slowdown linked to the great depression of 1929, the pivoting wheel (or with swivel castor) was created and, as a result, the possibility of using industrial castors grew further.

At the same time, the development of chemistry led to new discoveries. The other important steps were: the introduction of bakelite (1909); the creation of synthetic rubber (1930); the synthesizing of nylon (1935).

These discoveries favoured the predisposition of brand new solutions: the first plastic wheels were created and the possibilities for synthetic rubber treads increased.

In 1940 the first synthetic rubber tire was created and the pneumatic wheel could also be adapted to the castors.

During the Second World War, the chemical and metallurgical sectors gained momentum, paving the way for the post-war economic boom.

In 1955 polyurethane, a synthetic rubber from isoprene, was invented. In 1954 the Italian chemist Giulio Natta produced isotactic polypropylene.

The development of ergonomics and the consequent demand for ergonomic handling, together with a greater collective well-being, favoured, in those years, the development of furniture, which further expanded the range.

Today castors can be made of steel, plastic, stainless steel, aluminium and zamak. Industrial wheels can be made of metal, rubber or polyurethane coated metal, thermosetting plastic or thermoplastic, rubber or polyurethane coated plastic, pneumatic wheels with metal or plastic cores.

The applications are also the most diverse: from medical to industrial, from furniture wheels to those for the catering sector.

The wheels adapt to any type of surface, thanks to the countless variants that have developed over time and can bear any type of load.

Verification tests and safety standards for industrial wheels

The need to ensure safety, as well as to test real performance, led manufacturers to build, in 1980, a machine for testing the wheels and their castors. The parameters ranged from 30 to 2000 kg with travelling speeds not exceeding 16 km/h.

The project was financed by the Gruppo Ruote & Supporti di Anima and installed at Cerisie (Centre for Research and Development of Elastomers). The same machine is still available today to anyone wishing to carry out tests to verify the performance of a given type of wheel or castor.

A few years later, in 1988, the European manufacturers decided to improve the existing standards to regulate the use of industrial wheels and castors according to specific applications in certain sectors. Defining specific standards for example for wheels that can circulate inside hospitals, for scaffoldings, for waste bins.

Italian companies participated with enthusiasm and competence in the realization of this project. Thanks to the commitment of our country's technicians, Italy was appointed to coordinate the conversion work of the various projects within the different UNI - EN and ISO standards.

Most suitable industrial wheels in relation to the actual use

In conclusion, the need to move loads and products ergonomically, either by hand or by mechanical traction, as well as the request of modern society to reduce exertion in every activity, are the factors that have determined the success of industrial wheels over the centuries. Finishing lines that the major manufacturers have been able to cross, thanks to their ability to meet market demands, using all available technologies.

Are you interested in knowing the types of industrial wheels best suited to your specific needs, through a dedicated consultation? Contact our experts to get a no-obligation consultation specific to your project.