21

Dec

High temperature wheels

The market of industrial wheels requires that certain types of wheels can also be used in the most extreme environments.

We refer, in particular, to production and processing sites with extremely high temperatures. Therefore, wheels for trolleys or other handling equipment for goods or products must be manufactured so as to keep their performance unchanged in these contexts.

Examples of applications include trolleys for bakery ovens, industrial ovens, high temperature sterilisation and painting systems. More generally, the food industry, where different types of cooking are handled, is a sector where these wheels can be found, with the need to maintain their characteristics intact during and after exposure to large amounts of heat.

This article describes:

General characteristics of high temperature wheels

Wheel accessories: also designed for high temperatures

Focus on materials of high temperature industrial wheels

Silicone rubber

Thermosetting resin

Mechanical cast iron

Polyamide 6 charged with glass fibre

Wheel types suitable for high temperature contexts

Solid thermosetting resin wheels - Series 67

Monolithic wheels in polyamide 6 charged with glass fibre - Series 68FV

Cast iron solid wheels - Series 69

Silicone rubber wheels with aluminium centre - 72GS

Brackets for high temperature wheels

General characteristics of high temperature wheels

The temperature resistance is guaranteed by the manufacturers thanks to the use of specially designed materials, i.e. able to ensure the wheel resistance to deformation due to heat (in some cases even to very cold conditions).

The aim is to achieve the best combination of resistance to high temperatures and the necessary sliding performance when using trolleys and other handling equipment.

The temperature range that the wheels can withstand is between approx. -40 and + 400 Celsius degrees.

Wheel accessories: also designed for high temperatures

In this context, it is important to remind that, in addition to industrial wheels, the other components connected to them – in particular brackets, axles, bearings – must also be designed to withstand high temperatures.

Likewise, the products for treatment and maintenance of wheels must have characteristics compatible with high temperatures. In this case, the use of a specific grease that does not melt when certain heat thresholds are reached is essential.

For more details and insights, please refer to the complete list of products for high temperatures.

Focus on materials of high temperature industrial wheels

Below is the list of main materials used in the manufacture of wheels suitable to withstand extreme temperatures:

Silicone rubber

Silicone rubber, manufactured through a vulcanisation process, has a medium-high elasticity and guarantees an easy overcoming of obstacles even on uneven floors. It is able to withstand temperatures of 250°C.

Thermosetting resin

Thermosetting resin is a mixture of phenolic resins suitably charged with inert material, totally free of asbestos. The resin is moulded, compressed and then dried in the oven. It is able to withstand temperatures up to 300°C.

Mechanical cast iron

Mechanical cast iron is produced from a casting of EN-GJL-200 cast iron according to standard UNI EN 1561:1998. It resists up to 400°C.

Polyamide 6 charged with glass fibre

Polyamide 6, used for other Iberruedas series, is charged with glass fibre to increase its temperature resistance, and thus withstands heat up to 130°C.

Wheel types suitable for high temperature contexts

Iberruedas, a leading company in the field of industrial wheels, provides for four specific series for high temperatures:

Solid thermosetting resin wheels - Series 67

These are the most common wheels in trolleys for bakery ovens, used in food factories, bakeries, restaurants, supermarkets.

They are available with diameters between 80 and 200 mm, and have load carrying capacities up to 500 daN.

The version with bushing hole is available with different types of axles to meet different needs of handling, noiseless operation and durability.

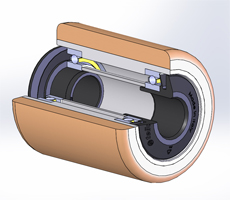

The version with hub with ball bearings lubricated with high temperature grease guarantees excellent performance and absence of squeaking, even for prolonged use and with heavy loads, and excellent resistance over time.

A version with stainless steel bearings is also available, for use in environments with aggressive chemicals and moisture. The ball bearings are protected from dust and dirt through steel or stainless steel threadguards.

This series is suitable for smooth and compact floors, including tiles and concrete-resin surfaces, and is also able to withstand chemical agents of medium aggressiveness. The high hardness of the material can damage delicate floors.

Link to in-depth data sheets

Monolithic wheels in polyamide 6 charged with glass fibre - Series 68FV

They are suitable for mainly static use, on smooth and compact floors and for medium carrying capacities. They are suitable for use with equipment that must be frequently washed and sterilised, in particular in autoclave. The excellent sliding capacity guarantees the minimum effort in manual handling, but only on smooth and resistant floors.

They are available with 100-125 mm diameters and with carrying capacities up to 350 daN.

They can be used on trolleys for indoor handling in food and canning industries and for tannery equipment.

Link to in-depth data sheet

Cast iron solid wheels - Series 69

This is a type of industrial wheels suitable for mainly static use and for high loads, such as tile kilns for ceramic industry or industrial furnaces in general.

Please note that the version with bushing holes is able to resists up to 400°C.

This series is suitable for smooth and compact floors and is also able to withstand chemical agents of medium aggressiveness.

They are available with diameters from 100 to 200 mm and with carrying capacities up to 1400 daN,

Link to in-depth data sheets

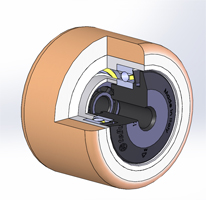

Silicone rubber wheels with aluminium centre - 72GS

It is a type of wheel particularly suitable for use in bakery ovens, where its maximum stay at 250 °C is 30 minutes, followed by a period of stay at room temperature of at least 30 minutes.

It features excellent elasticity characteristics and guarantees easy overcoming of obstacles also on uneven floors.

Compared to monolithic wheels for high temperature, it allows a significant reduction in noise during use. It is stain-resistant and protects delicate floors.

Available with 100 mm diameter and 80 daN carrying capacity (40 daN at high temperatures).

Link to in-depth data sheet

Brackets for high temperature wheels

Iberruedas high temperature wheels are combined with light (NL) and light stainless steel (NLX) brackets in a specific version for high temperature environments.

It is recommended to check the performance of the single wheels at high temperatures, as the heat increase reduces the load carrying capacity of the single wheel. Iberruedas catalogue contains a table with the decrease in load carrying capacity in relation to the temperature. To request it, please directly contact the company.